Saturday 30 December 2017

Perfect Edge Joints

I've started making a small walnut four drawer chest. In order to get continuous grain I'm making the top and sides from a pair of 1/2" thick book matched board, which are too long to edge joint on my shooting board. I'm planing both edges at once using my jointer plane with side fence. The two boards are 'hinged' to ensure a flat result.

Above you can see the two nicely rippled book matched boards and below the joint pushed together.

When I have such a nice close fit, I just use stretched masking tape on both sides to clamp the joint.

The lack of pressure doesn't introduce any stress into the joint and it should stay nice and flat.

I planed the shorter sections individually on the shooting board using my Veritas plane. You can see I've taken the rear handle off so that I can grip nearer the blade which gives me much more control and feel (thanks for the tip Bern).

Below are the two boards sitting one on top of the other, with no visible daylight between. You can see the 'up' and 'down' marks that remind me which way to face each board to ensure a flat panel results.

Friday 29 December 2017

Scandinavian Design

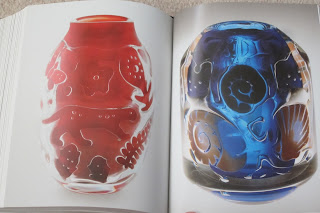

In my Christmas stocking was this fascinating book, it may be only A5 in size but is 700 pages long with beautifully shot photos. It is sectioned by each country, Sweden, Denmark, Norway, Finland and Iceland indicating the differences in style between them. Of course there is strong representation of furniture designers, chairs in particular, although I found it all really interesting. I've taken a few shots below to give an idea of the contents, it's a great little book and easy to dip in and out of.

Sunday 24 December 2017

Beautiful Toolbox from Fine Woodworking Magazine.

Robert from Canada sent me these pictures of a fine looking toolbox he has just completed, a Christmas present for his son. It was made from an article by Mike Pekovich with protruding through tenons, bridle joints and dovetails on the drawers. The dovetails were cut as through dovetails and turned into half blinds with the addition of thin curly maple fronts, a great technique and one I've used many times before. The carcass is cherry, the hardware is from Lee Valley and the brass stay is from Brusso. I think that will be one happy son on Christmas day!!

Thursday 7 December 2017

Perfect Dovetail Spacing

I've seen woodworkers go to great lengths to ensure their dovetails are evenly spaced out, the Alan Peters method using callipers works very well. However I've always eyeballed my marking out as small differences in dovetail spacing are not picked up by the eye.

What I do find immediately noticeable is a variation in the width of the pins. I've been toying with the idea of making a double kerf starter which would make identical sets of kerfs to place the saw blade in, but then I remembered I had kept all my used Japanese saw blades over the last 20 years. So with two of these blades, a piece of thin veneer and some double sided tape, I made my own double bladed kerfing saw.

Run up against a square (or using my 90 degree magnetic guide) the test results were impressive, giving perfect pairs of cuts from which the tails could be cut. The technique would be equally well suited for cutting dovetails freehand or with one of my magnetic guides.

This spacing is suitable for finer dovetails leaving an overall gap (with the waste removed) of just 1.75 mm. This was achieved using two 372 saw blades with a 0.6 mm thick veneer stuck in-between.

Whilst I was at it, I made up a thicker version with an overall 2.5 mm spacing for larger carcass dovetails.

Tuesday 5 December 2017

Sussex Guild Craft Show in Midhurst

We had the pleasure of visiting the Sussex Guild Craft show at Midhurst over the weekend.

There was strong showing of furniture makers among the numerous exhibitors.

These nesting tables and lovely dining room table are by Edward Johnson.

The box below, made by Andrew Poder, caught my eye, the lid was made by embedding burr oak off cuts in polyester resin.

He used the same technique with these sculptures. I've ordered some of the polyester resin to have a little play.

These block prints are simply amazing! Cut in boxwood by Sue Scullard, the master block for the print below (Edinburgh castle) took two months of painstaking work.

James Mursell with his excellent Windsor chairs was at the show promoting his courses. If you've ever fancied having a go I can highly recommend them, very rewarding for all skill levels.

I'm just testing my favourite of his chairs, a beautiful rocker.

Another very skilled artist was Simon Groves with these wonderful carvings.

......and yes they were all done with this chainsaw!

Lastly this large vessel was turned by John Plater from a huge walnut root ball, he must be stronger than he looks!

Subscribe to:

Posts (Atom)