Tuesday 30 September 2014

New English Workshop, Courses for 2015.

After the very successful and popular courses run by Chris Schwarz this year he's coming back for 2015. This time however he will be accompanied by more famous tutors from the US, Peter Follansbee, Tom Fidgen, Jeff Miller and the legendary Roy Underhill. You can see details of the dates and costs here http://www.newenglishworkshop.co.uk/

I will also be running a course making my tool chest with piston fit trays, for those of you who haven't seen it yet, watch here https://www.youtube.com/watch?v=SI0kAuCqsdc&list=UUQ_C2mk-aqY6PizFuQWypxg

This years courses filled up very quickly, so if you want to attend don't delay, you've been warned!

Sunday 28 September 2014

Green Sleeves Quality Felt Tool Bags

I saw these advertised on E Bay and they looked very nice, when they arrived they didn't disappoint.

Hand made with 100% real wool felt, with a cotton ribbon and a leather closer. The felt is nice and thick giving great protection for your best planes.

They come in 19 different sizes from 6"x4" right up to 26"x10" and range from £6 up £36. And if that's not enough they also offer a bespoke service..

My two Sauer and Steiner planes now have the protection they deserve.

If you are interested just look for Green Sleeves Tool Bags on E Bay, the seller is Tea and Teak

Friday 26 September 2014

New Veritas Bench Planes

At the WIA show Veritas had something to unveil (in typical North American style!)

And here it is a new range of bench planes, they are heavy, solid and look a lot better than the originals.

With each of the five models there will be choices, lots of them! You can choose your blade angle in one degree increments as well as the type of blade, the style of the tote and the shape of the front bun.

I think all this choice is great for the experienced hand tool user, although I think those less experienced will need some help and guidance to make the correct choice.

I still feel the best workshop plane is a jack plane with a 45 degree angle and a nice tool steel blade, but then maybe I'm a bit old fashioned! I would also go for a smoother around 55 degrees to handle difficult grain.

So there we go a great new range of planes which I'm sure will be available this side of the pond in the very near future, well done Veritas!

Wednesday 24 September 2014

Customer Dovetails.

First up is a nice chisel box made by Kat in California, she commented, 'I'm absolutely loving the dovetail guide. I also enjoy your inspiration and website / blog. I thought you would enjoy seeing my VERY first hand cut dovetail project, a box for my chisels. Your guide was a great help. I didn't use anything but hand tools, including the making of the grooves, rabbets and dados. Thank you!'

It looks like some nice chisels to go inside as well.

Here's a practice piece with the guide (always a good idea before committing to the real thing) from Russell in the US. He said he ended up with a few gaps but it was definitely much better than without the guide, looks pretty good to me!

Monday 22 September 2014

Roubo Split Top Workbench.

Here's a fine and massive Roubo bench made by Ben in the UK. It's about twice the size of mine!

It's 7' 6" (2300mm) long x 29" (730mm) deep x 35" (900) high.

It's made from German beech and the top is 4" thick (100mm) across the full width. The legs are 5" square (125mm). It took 150 - 200 hours to complete and the material cost alone was £800 ($1,300).

The Japanese style sawhorses are used for more intricate work.

Both vice screws are standard ones from Veritas.

The top was attached with a tenon and a 1:8 dovetail on the outside, although Ben said this was barely visible and he would use a 1:6 or 1:4 next time. I used 1:1 on mine ie 45 degrees.

You'll notice the back leg was angled in order to provide extra support at the rear for the large overhang. It's a nice touch although he admitted with a massive 4" thick top it probably wasn't necessary. The jaws were padded on both sides and the vice chop is an elegant understated shape.

The sliding deadman is equally elegant and slides on an upturned 'V' runner to avoid a shavings trap.

If you don't want to hunt for your dogs, put one in every hole!

A nicely made tail vice using an inexpensive bench screw. Note the runners are screwed on which makes them accessible should things need adjusting in the future.

Rising stops were fitted to each end of the bench for planing against, great for both British and Japanese style planes.

The slats for the undershelf are interesting, one side is at 90 degrees and the other is angled to match the angle of the offset rear leg. With careful measuring and using an odd number of slats the shelf was completed without an odd shaped piece at the end. This was indicative of the thought that went into this fine bench. Thank you Ben for sharing.

Friday 19 September 2014

American Woodyard

While we stayed in Asheville I called into Asheville Hardware which was a bit of a mix. They are a Festool distributor, a dealer in secondhand tools and machines as well as selling lots of timber. The room downstairs had lots of large end reared boards, this is the way to sell timber. When it's all stacked in piles (that require lots of effort to uncover) it tends to stay that way.

This large stump that would make a great coffee table with a slab of glass on top.

Two huge walnut book matched planks below caught my eye.

There were good areas of figure but at $2,500 per board they were a bit steep.

More planks of nice dry wood.

A very large board of osage orange, very tough and heavy. This was the first time I had seen this wood, it would be great to makes some planes with.

Another book matched pair of figured and coloured maple boards, I'm sure James Krenov would have made good use of these.

To round off my posts on our trip to the US I'll leave you with Barnes and Noble. If you thought the internet had killed off books, then somebody forgot to tell them!

The store was enormous.

They had a well stocked woodworking section, the one English book was by Mark Ripley.

An equally well stocked magazine rack with a better showing for the Brits.

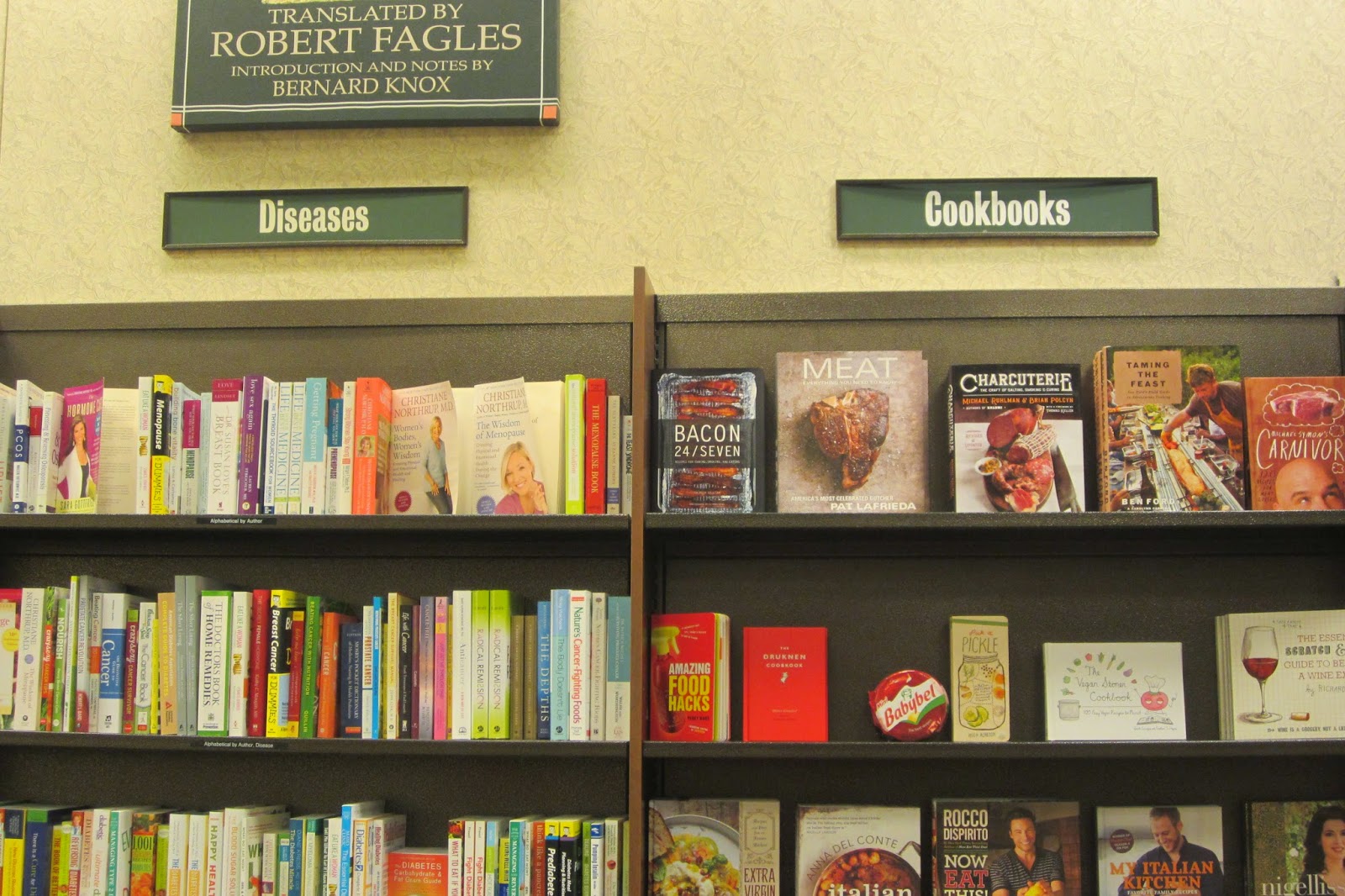

And I'll leave you with this shot which could be viewed two ways, a massive faux pas or a very observant reflection on the American diet.

Tuesday 16 September 2014

Brian Boggs Open House Saturday September 20. 3.00-7.00 PM

This coming Saturday there is an Open House at Brian Boggs impressive new 10,000 square feet premises. It includes workshop tours, demonstrations, a wood slab sale, free access to the furniture gallery as well as food and drinks. And if that wasn't enough there's a raffle to win a Sunniva swing bench! I wish I wasn't going back to the UK tomorrow.

We did a big detour to take in a visit and Brian's very knowledgeable wife Melanie very kindly showed us around. The lobby had a number of maquettes on show, it's amazing how cute these miniatures look.

Here's an outdoor rocker which looked particularly nice in oak.

Below is one of his classic rockers with hickory bark woven seat and very comfortable it is too.

Upstairs is a wonderful walnut dining table and chairs, what a lovely rich colour.

The rocker again, this time without me obstructing the view.

The rear of the wonderful chair I saw at the WIA show, a real head turner.

Melanie told me that all Brian's chair were numbered and this is number one, the first chair he ever made over 30 years ago. Apparently he lacked proper tools at this time so the mortice and tenon joints for the back slats were cut with a sharpened screwdriver!

This ingenuity was stretched to the limit with amazing home made machine for processing hickory bark into perfectly prepared and dimensioned strips for weaving the seats of his chairs.

Apparently it has numerous cutters inside and can produce strips the length of the tree, amazing.

There were very good stocks of Honduran Mahogany which is used for the outdoor seating. This was sourced from local small producers in Honduras and Brain has made more than one trip down there to set this up. The different coloured ends denote different farms.

The 'follower' setup below was for the seats for his musicians chair. Now this I can understand this much better than the bark machine! They investigated having these seats CNC machined but they could not get within acceptable tolerances, just goes to show any machine is only as good as the person operating it.

The result is an even set of cove cutter marks defining the exact symmetrical shape of each seat. They offer this very tactile surface as an option to the normal smooth one and if I were buying one of these it would be the one I would choose. A lovely textured balance to the smoothness of the rest of the chair.

Here's the monster band saw which makes David Finck's look like a toy! (read the other posts).

It's used to cut the laminations and with a carbide tipped blade produces results that are ready for gluing straight from the saw.

All the while we were being shown around Brian was buzzing around in the back ground. It looked as if any disturbance would be unwelcome so I kept my distance. I'm sure Saturday afternoon will be completely different so if you're anywhere near Asheville NC this is one open day not to be missed!

Subscribe to:

Posts (Atom)